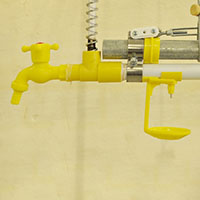

TARIMAR NIPPLE WITH CUP

- DRINKING SYSTEMS -

- The ideal solution for a high-efficiency flock production using the same nipple from day-old chicks to killing.

- Presents a clean and ergonomic appearance with its saddled cylindrical PVC pipe assembled using ultrasonic welding and its carrier pipe manufactured of galvanised sheet metal.

- Cups are placed underneath the nipples.

- The plastic valve regulator and the terminal prevent any metal from contacting the water.

- It presents a suitable and economical solution for broiler breeding.

Nipple

Ensuring the supply of thesystem water in the PVC pipe, it is the most important part of the system. Thebird causes the water to flow into its beak by pushing the stainless steelsection at the end.

Nipple Saddle

The socket part enablingthe robust assembly of the nipple to the PVC pipe. This part is attached to thePVC pipe through the use of ultrasonic welding.

Nipple Cup

A single unit is assembledwith each nipple. It ensures the interconnection of the carrier galvanised byand the PVC watering pipe with its monoblock S shape structure.

Regulator

Ensures water at the samepressure at each point on the watering line. Eliminates pressure differences inthe watering line caused by sloping in the poultry house.

By-pass Regulator

In addition to thefunctions of a normal regulator, it features a bypass system that enables theregulator system to be bypassed during cleaning after a flock. This alsoenables the pressurised flushing of the pipes.

End Assembly

Mounted at the end of thewatering line. Used to discharge the water in the line after flocks.

Electro Shock Unit

It gives small electric shock to the wire on the support pipes. So it prevents the birds perch on the system.

| Maximum Line Length | 150 meters |

| Watering PVC Pipe Diameter | 26,7 mm |

| Recommended Number of Birds Per Nipple | 10 - 15 Broilers |

| Nipple Interval | 20 cm ya da 25 cm |

| Nipple Watering Capacity | 65 ml / minute |

| Carrier Galvanised Pipe Diameter | Ø 32 mm (3,2 cm) |

| Carrier Galvanised Pipe Wall Thickness | 1,00 mm |

| Lifting System Carrier Roller Range | 3 meters |

| Main Rope Thickness | 4 mm Stainless Steel |

* This table was prepared considering standard manufacturing conditions. Technical properties may vary according to our customers' demands and any variations in the structure of the poultry house.

Single Filter ( against dregs )

Placed at the inlet of the main watering line in the poultry house. Purifies the water to be supplied to the poultry house from dregs.

Dual Filter ( against dregs and lime )

Placed at the inlet of the main watering line in the poultry house. Purifies water to be supplied to the poultry house from dregs, and regulates the water quality through its lime filter.

Medicator

A medication pump that allows the regular administration of required liquid vitamins and medications at the required dosage and equally to all lines in the nipple watering system.

Electronic Water Meter

Allows the metering of the amount of water consumed in the poultry house. Also, when integrated into a computer system, it can provide information including the daily water consumption of a bird. It should be noted that a significant reduction in water consumption in the poultry house may indicate the onset of a serious disease.

Manual Wall Mounted Winch

This is a spinning winch allowing the system to be lifted manually in poultry houses up to 60 metres.

Ceiling Winch

A ceiling winch allowing the system to be lifted manually in poultry houses up to 80 metres.

Hoist with Chain

A hoist system for lifting the system manually through the use of a chain system, mounted separately for each feeder line.

Motor Powered Lifting Winch

A system capable of automatically lifting minimum 2 lines simultaneously through the use of a motor reductor.